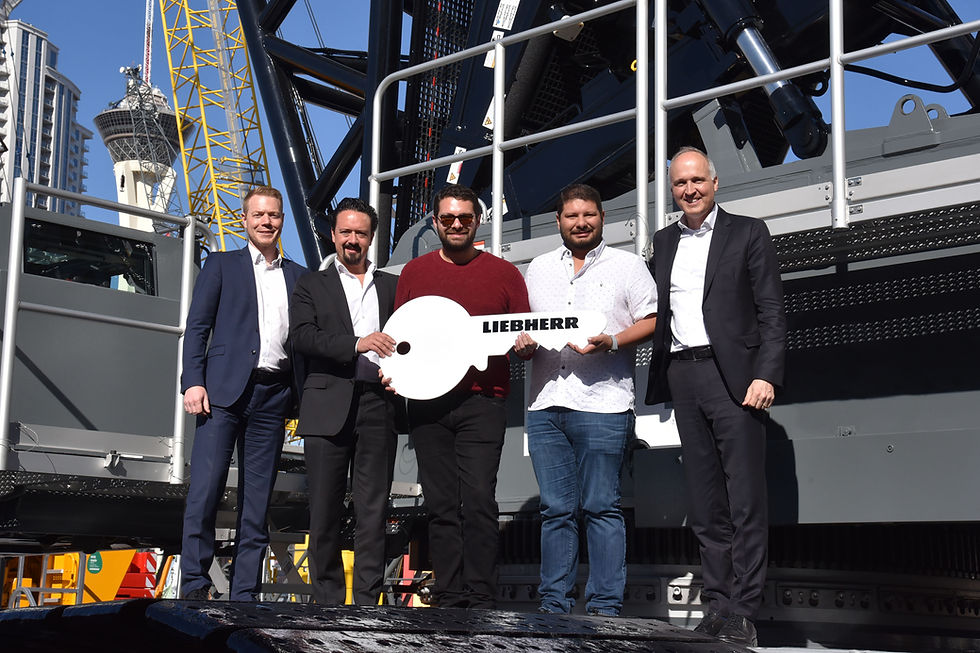

ESEASA Placing the order at Conexpo 2023 (from left to right): Daniel Pitzer (CFO Liebherr-Werk Ehingen GmbH), Christian Tableros (Sales Director Liebherr Mexico), Abraham Santos (Owner ESEASA), Aldo Santos (Owner ESEASA), Jan Liebherr (Chairman of the Board of Directors of Liebherr-International AG)

ESEASA ordered the Liebherr 700-tonne crawler crane at Conexpo 2023 as part of a package that included a Liebherr LTM 1250-5.1 and two LRT 1090-2.1 rough-terrain cranes. A Liebherr LTM 1150-5.3 has since been added to its fleet. Santos always appreciates having a direct line to Liebherr and its reliable service around the clock. “We require competent service and fast solutions for our projects. We cannot accept delays, we need solutions on the day,” explains Santos. “Liebherr provides us with excellent support and also ensures that well-trained technicians are normally available. We also appreciate the high quality of Liebherr cranes.” The main areas of work for ESEASA include the energy sector, such as petrochemicals and wind power.

Handover in Mexico (from left to right): Christian Tableros (Sales Director Liebherr Mexico), Aldo Santos (Owner ESEASA), Dolores Coronado (Operations Manager ESEASA).

The LR 1700-1.0W is the successor to the LR 1600/2-W and is currently the most powerful narrow-track crawler crane on the market. Company co-owner Aldo Santos says: "We opted for the LR 1700-1.0W because it is significantly more powerful than its predecessor. It also offers state-of-the-art crawler crane technology." Narrow-track crawler cranes are optimized for use in wind farms: they can travel from one turbine to the next along the existing routes and be deployed very quickly. The biggest differences between the LR 1700-1.0W and its predecessor model, the LR 1600/2-W, are the new crane's significantly higher lifting capacities and lifting heights. The new crane thus meets the more challenging requirements of working on modern wind turbines with hub heights reaching 170 meters. Liebherr also offers the LR 1700-1.0W with a luffing jib. This option was not available for its predecessor.

The 700-tonne crawler crane loads offshore components on a wide chassis in the port of Anahuac, Veracruz.

The LR 1700-1.0W offers more power and a greater lifting height than its predecessor, the LR 1600/2-W. This gives it the best prerequisites for the efficient assembly of modern wind turbines on wind farms. To meet the challenging demands for driving and steering, Liebherr has equipped the crane's new narrow-track travel gear with components from its next larger crane class. In a nutshell, it is a narrow footprint with high load capacities, which is the concept behind the LR 1700-1.0W. The new 700-ton crane is thus the benchmark for narrow-track cranes worldwide. The superstructure and equipment are identical to those of the successful LR 1700-1.0.

The V-frame and VarioTray have more than proven their worth on the LR 1700-1.0, LR 1800-1.0, and LR 11000 crawler cranes. As a result, these innovative systems are also found on the narrow-track version of the LR 1700-1.0. The "VarioTray" is a small counterweight frame that can be unbolted quickly and easily as required. This eliminates the need for tiresome stacking and unstacking of counterweight plates. The V-Frame ballasting system is a hydraulically adjustable folding frame that allows the ballast radius of the 700-tonne crawler crane to be adjusted continuously between 13 and 21 metres. A rigid ballasting system is thus no longer required for large radii. These innovations offer great advantages, especially for wind turbine assembly.

The LR 1700-1.0W offers state-of-the-art crawler crane technology such as V-Frame and VarioTray.

The LTM 1250-5.1 features enormous load capacities. The Liebherr designers had a clear concept to follow in the development of this crane to get the maximum lifting capacity from the available weight of a 5-axle mobile crane! The result is that the LTM 1250-5.1 is now the most powerful crane on five axles in the world. VarioBallast® enables it to deliver maximum lifting capacities with a large ballast radius, making it perfect for use on constricted sites with a small ballast radius. And it achieves this by quickly adjusting the ballast in seconds. The crane can be fitted with a multi-functional folding jib, a long lowering fixed jib, or a rigid powerful jib. The proven VarioBase®, ECOmode, and ECOdrive technologies make the LTM 1250-5.1 particularly safe and efficient.

The LRT 1090-2.1 rough-terrain crane was designed primarily to deliver a high safety level. It is fitted as standard with an outrigger monitor, which automatically detects the support status and includes it in the crane control system. Do you want even more safety? Then it is delivered as standard by the VarioBase® variable support base. It enhances flexibility on site and also increases the crane’s lifting capacity. The telescopic boom on the rough terrain crane features time-tested rope pull technology. This telescoping technology enables the boom to be extended quickly to any length using a two-stage hydraulic cylinder with a rope extension mechanism. The system is very easy to operate and it enables you to set the perfect lifting capacities using two different telescoping paths, for either power or length.

With a maximum lifting capacity of 150 tonnes (175 USt) and a long telescopic boom, the LTM 1150-5.3 is the perfect addition to Liebherr’s crane range below the LTM 1160-5.2. With an axle load of twelve tonnes (26,450 lb), the crane can carry nine tonnes (19,800 lb) of ballast on public roads. This ballast enables it to complete lots of jobs without requiring an additional vehicle to transport the ballast. Its powerful telescopic boom can be extended with lots of add-on jibs. These are compatible with many of Liebherr’s cranes with lifting capacities between 100 and 180 tonnes (220,500 lb and 396,830 lb). Liebherr has continued its single-engine strategy on this crane with a mechanical drive unit for the superstructure. The weight reduction created by the elimination of the superstructure engine is used to deliver a longer boom and more lifting capacity.

As ESEASA intends to use the new crane in the wind energy sector and in industrial, oil, and gas applications, the wide standard chassis was also ordered. This allows the LR 1700-1.0W to be driven on-site with a load on the hook. ESEASA has once again secured a project for six oil drilling platforms, covering engineering, procurement, and construction the LR 1700-1.0W is essential for the assembly of these offshore platforms.

After the purchase of SEVEN Rough Terrain Cranes in 2021, having achieved many successful projects and being satisfied with Liebherr as a manufacturer, ESEASA ordered five more rough terrain cranes and two all-terrain cranes from Liebherr at the 2022 Bauma show in Munich, Germany. The new LRT 1130-2.1 rough terrain crane, also exhibited at the 2023 Conexpo show, was included with three units in the order. Shortly before Bauma, in spring 2022, Santos and his company already enlarged the fleet in the rough terrain crane segment with five LRT 1090-2.1 and two LRT 1100-2.1 models. The order at Bauma also included two all-terrain cranes, an LTM 1120-4.1 and an LTM 1250-5.1.

ESEASA’s head office is located in Mexico City. The company also owns a site covering more than 600,000 m² in Tampico in the state of Tamaulipas. The group mainly works in the energy sector; wind power and oil industry and has specialized in engineering, logistics, and crane assembly for large projects in Central America and the USA. The company has a 1500-strong workforce and a total of over 300 cranes of every conceivable type.

ESEASA operates Liebherr LRT rough-terrain cranes, LTR telescopic crawler cranes, and LTM all-terrain cranes including a large number of LTM 11200-9.1s and LTR 11200s, Liebherr's largest telescopic cranes. The company’s crane fleet also includes powerful Liebherr crawler cranes, such as the LR 13000, one of the largest crawler cranes in the world. "Liebherr offers innovative and safe crane technology. Their after-sales service and technical support are the best on the market," said Aldo Santos. ESEASA company co-owner Abraham Santos adds: "Liebherr cranes have the best cost-benefit ratio, retain their value exceptionally well, and therefore offer a high resale value."

Comments